How Do Refrigerated Vans Work? All Your Burning Questions Answered

Exactly how do refrigerated vans work? In this guide, we’ll be breaking down step-by-step the ins and outs of refrigerated vans and how you can choose the best build for your business.

So, you’ve decided you need a refrigerated van. Welcome to the world of refrigerated transport!

Whether you’re an experienced Transport Manager with large fleets of refrigerated vans, or a small business owner looking to buy your first, knowing the mechanics of how they work is always a must.

Refrigerated vehicles come in all shapes and sizes. From smaller van models such as a Peugeot Partner to 7.5-tonne lorries that travel across continents.

Fundamentally, though, they all work in a similar way.

So, exactly how do refrigerated vans work? In this guide, we’ll be breaking down the key components of a refrigerated van, how these components vary, as well as how you can make sure you’re buying the right one for your business.

Let’s dive in.

Browse Our Award-Winning Range Of New Refrigerated Vans Here – All Complete With FREE UK Delivery

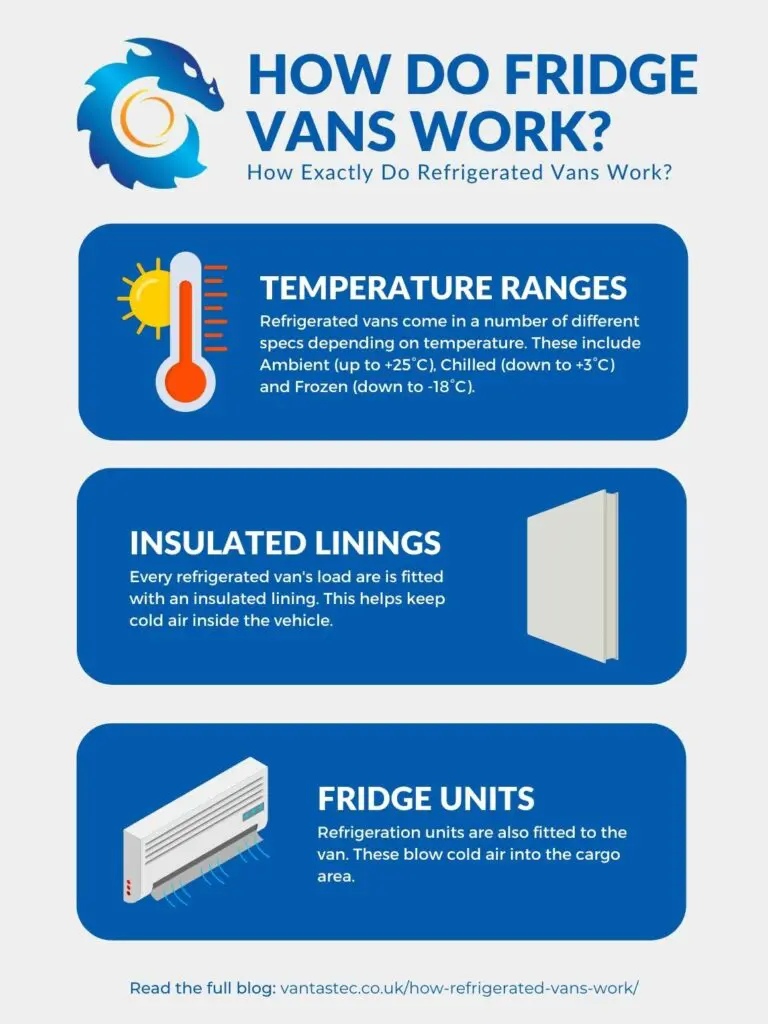

How Do Refrigerated Vans Work?

Refrigerated vans are also commonly known as chiller vans, fridge vans and even reefer vans. So, if you see us mention any of those phrases later on in this guide, just be aware that they all mean the same thing.

Freezer/frozen vans and ambient vans, however, are two totally different things. But we’ll discuss that in more detail later on…

In the simplest way possible, refrigerated vans work via two key elements: high-quality insulation and mounted refrigeration units.

First, an insulated lining is installed in the van’s rear compartment. Refrigeration units are then fitted, which blow cold air into the van’s load area.

These two pieces of kit work in tandem to help maintain your desired temperature. When you switch on the vehicle’s ignition, the refrigeration equipment will kick in.

It’s as simple as that. No trickery or magic. Just quality equipment installed by qualified engineers.

However, when it comes to buying a refrigerated van, one size doesn’t fit all.

A lot of thought and guidance goes into ensuring you have the correct specification for your business.

Let’s break down every aspect of how refrigerated vans work in greater detail, helping you choose your ideal build.

Temperature Ranges

The first step in deciding which refrigerated van you need will be determining your desired temperature.

This is one of the very first questions we ask customers when they enquire about a new fridge van.

Different products require different holding temperatures.

For instance: for long-term storage, ice cream needs to be kept at -18 °C or below (source: Marshfield Farm Ice Cream).

Meanwhile, according to the Specialist Pharmacy Service, pharmaceutical products such as medicines often need to be kept between 8°C and 30°C.

When it comes to temperature-controlled vehicles and the different builds available, they can be broken down into four main categories:

Ambient: Up to +25 °C

Chilled (aka fridge, refrigerate, or chiller): Down to +3 °C

Frozen (aka freezer): Down to -18 °C

Deep frozen: Down to -25 °C

Whatever you do, please ensure you’re transporting your products at the necessary temperatures.

Choosing the right temperature for your van protects the integrity of your products. Otherwise, your cargo can become spoiled – and, more importantly, unsellable.

If you’re unsure what temperature your goods need, check with your local authorities or contact the product’s manufacturer – if you didn’t make it yourself, of course.

Once you’ve decided on the temperature ranges you need, you can move on to building the appropriate conversion for it.

High-Quality Insulated Lining

Second, the lining.

Every refrigerated van’s load area is fitted with an insulated lining. The make-up of the lining, however, depends on where you buy your refrigerated vehicle from.

For example: at Vantastec, our fridge van conversions feature re-inforced GRP linings, which are insulated, seam-free and leak-proof.

Generally, the goal of every refrigerated van’s lining is the same: to maintain temperature. Even under the most demanding circumstances.

It’s also worth noting the thickness of a fridge van’s lining can depend on what temperatures are needed.

For instance, chilled spec vehicles often come with a 50mm thick lining, whereas frozen spec vehicles feature 75mm linings.

Thicker linings are installed when lower temperatures are needed. This is to minimise warmer temperatures outside of the vehicle creeping into the cargo area, as well as make sure cold air doesn’t escape.

Refrigeration Systems

Refrigeration systems are the workhorses of every fridge van.

Yes, every element of a refrigerated van needs to work in harmony to maximise performance. But the refrigeration system is what actually blows cold air into the van’s cargo area.

As you can probably guess by now, there are different refrigeration systems for different requirements: chilled and frozen.

Depending on the temperatures you need (as outlined in the above paragraph), you’ll need either a chilled or frozen unit.

Both types also come with the option to add overnight standby. This allows you to plug your van’s fridge unit into a domestic electrical socket to keep your products cold when the engine isn’t running.

This is ideal for businesses that want to reduce the amount of time they spend loading and unloading their vehicles.

If maintaining a precise temperature is of utmost importance, it could be worth ordering one with a heat/cool system.

Most refrigeration units have a cooling function. But not all feature a heating one.

Let’s use another example.

Pharmaceutical products need to be kept at very strict storage temperatures. Let’s say a particular product needs to be kept at 8°C. No higher. No lower.

In warmer weather, a regular chilled refrigeration unit with just a cooling function would work just fine.

But what happens when the weather gets colder, and the temperature outside is colder than the one you need inside your van?

Cold outdoor temperatures might bring the van’s load area below 8 °C. Spoiling all of your cargo.

This is where the heat/cool function would kick in. The heating function would then raise the van’s internal temperature to meet the required number; which in our case would be 8°C.

Pharmaceutical spec vehicles often need a lot more care. We’ve provided tailor-made vehicles to some of the UK’s largest pharmaceutical distributors. So, please feel free to get in touch or leave a comment if you have any questions about this.

Additional Extras

It may also be necessary to install some additional extras to your van.

Some, such as thermal curtains, adjustable bulkheads or slab doors are designed to maximise your van’s performance.

For example, we always recommend businesses have thermal curtains installed if they open their van’s doors often. This is to minimise outside temperatures affecting your vehicle’s internal temperatures.

Others such as shelving units, meat hooks or overnight standby are designed for functionality and improving efficiency.

Some businesses, for example, might need shelving installed so they can pack as much produce in their vehicle as it will allow.

Whatever your requirements, the chances are there’s a van extra that’ll make your life easier.

If you’re unsure whether you would need additional extras fitted to your vehicles, please feel free to get in touch with our team.

How Fridge Vans Work: Frequently Asked Questions

What Are Refrigerated Vans Used For?

Refrigerated vans are used to transport goods that need to be kept at cold temperatures.

Some of these goods include fruit and veg, meat and poultry, cakes, fresh fish, pharmaceuticals and even fine art!

Do Refrigerated Vans Use More Fuel?

Fuel consumption varies from vehicle to vehicle.

Factors such as distance travelled, temperatures, driver behaviour, vehicle type and more all affect how much fuel you use.

This makes it difficult to give a definitive answer on whether refrigerated vans use more fuel without extensive testing.

What we will say, however, is that a fridge van’s equipment will add to the vehicle’s gross vehicle weight.

Combined with the total weight of the goods you’ll be carrying, particularly in high-traffic areas, this could impact your fuel economy.

What Are The Benefits Of Having A Refrigerated Van?

You can take your products directly to your customers!

We’ve been fortunate to help countless independent businesses grow their operations. All thanks to having the ability to now take to safely deliver their products wherever they please.

How Much Does A Refrigerated Van Conversion Cost?

This depends on a number of things, such as the size of the vehicle and the specification you require.

Different converters will charge different prices as their costs for materials and labour will vary. If you’re looking for a quote on a refrigerated van conversion, get in touch with our team today.

What Is The Best Refrigerated Van To Own?

This also depends on your needs.

Size, price, fuel economy and warranties are all key considerations for choosing a new refrigerated van.

Some of which you might find more important than others.

We’ve previously put together a list of seven of the best refrigerated vans you can buy for your business. We recommend starting there.

Summary: How Chiller Vans Work

The world of refrigerated transport can be daunting. If we’ve missed anything, or want to dive deeper into learning more about our world, feel free to check out our full range of van-buying guides.

If you’ve made it this far, you’ll hopefully no longer be asking yourself the question ‘How do refrigerated vans work?’

Now, we’d love to hear from you.

Do you have any follow-up questions about the topics we covered today? Any topics you’d like us to cover in-depth in the future? Leave a comment below, and we’ll get back to you as soon as we can.

Take care, everyone!

Read next:

- The 7 Best Refrigerated Vans Your Business Needs In 2025

- How To Maintain Your Fridge Van’s Temperature In The Summer

- Transporting Pharmaceuticals In Vans: 6 Simple Tips You Need To Know